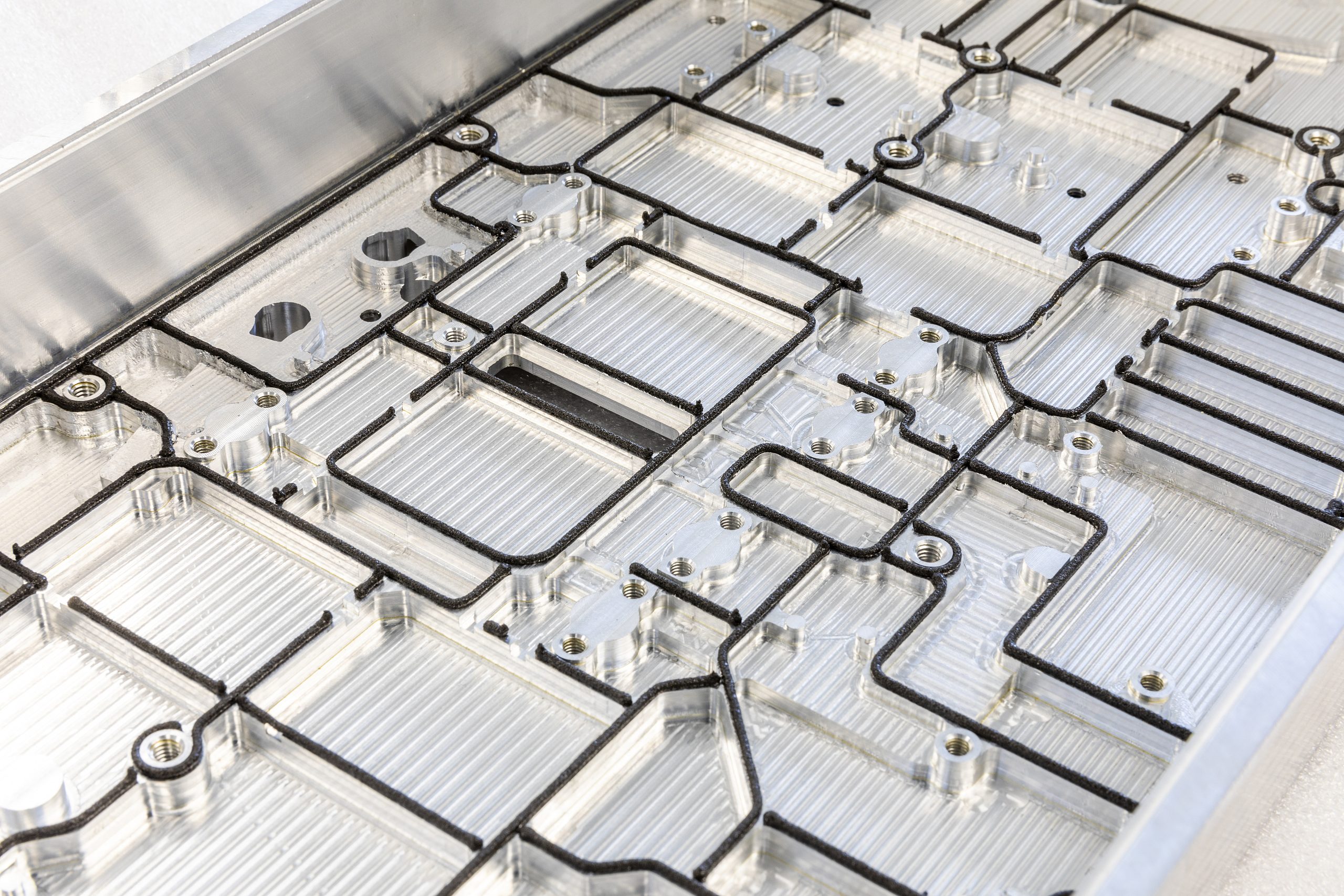

Unlike traditional gaskets, which are pre-cut and applied, form-in-place EMI gasketing involves dispensing a liquid elastomer material directly onto the sealing surface, where it then cures in place to form a custom-fit gasket. This process offers several advantages, including the ability to create intricate shapes and seal complex geometries with high precision. Additionally, form-in-place EMI gaskets provide excellent electrical conductivity and thermal stability, ensuring reliable performance in demanding applications such as military equipment, telecommunications systems, and medical devices. With its versatility and effectiveness in shielding sensitive electronics, form-in-place EMI gasketing has become an indispensable solution for engineers seeking robust EMI protection.

At Mitacor Industries we work with our customers to find the correct gasketing solution for their needs. We have extensive experience in FIP gasketing, having worked in the telecommunications industry for many years, working with different gasketing materials. Using our knowledge paired with our cutting edge machinery, we are able to dispense FIP gasket along various complex patterns.